Your Trusted Paving Partner

When You Think Asphalt, Think Eosso

We’re the trusted provider of paving maintenance, repair, and installation services among New Jersey, Eastern Pennsylvania, and Delaware. Contact us today to learn more or schedule a service.

Our Services

From parking lots to sidewalks, transforming surfaces is our specialty. As the nation’s top pavement service provider, we tailor our solutions to suit each paved area on your property. Check out our services to see which one is right for you.

Who We Serve

We’re the trusted paving partner for clients across markets. Backed by a proven portfolio of successful asphalt and concrete projects, we deliver the results you want when you want. Find your industry below to learn more about the services we offer.

The Eosso Brothers Paving Experience

Eosso Brothers Paving has delivered top-notch pavement management services throughout NJ since 1992. For more than 25 years, founders Gary and Thomas Eosso have learned the importance of providing quality workmanship and forming strong customer relationships built on trust and character.

Eosso Brothers has built an industry-wide reputation of dependability, quality work, and reliable customer service. When you trust us with your next paving project, you can rest easy knowing we care about our customers.

Initial Estimate

The Proposal

Contract Signing

Project Planning

Project Completion

We’re Proud Members Of:

The Premier Paving Provider in New Jersey & Surrounding Areas

As your local paving provider, we serve clients throughout New Jersey, Eastern Pennsylvania, and Delaware. Wherever you are, we’ll come to you. Our local expertise allows us to understand your needs and address them right the first time.

Our Office:

- Farmingdale

Our Service Areas

New Jersey’s Premier Paving & Concrete Provider

Eosso Brothers Paving is the trusted name for reliable maintenance, repair, and installation services in communities throughout New Jersey, Eastern Pennsylvania, and Delaware.

Our Office:

- Farmingdale

383 Cranberry Road Farmingdale, NJ 07727

Have a job that isn’t within our service area? No problem. Our Pave America partners are here to help.

Hear From Satisfied Clients

See our testimonials to see what others have said about experiencing the Eosso difference.

“This is one of the most professional, thoughtful, and courteous operations I’ve seen in a long time. First, it was the map and I just saw them wheeling residents’ trash containers to areas that will be accessible today…just incredible! Kudos to the Board for selecting this contractor! By the way, and most importantly, the sealcoating looks amazing! Think you know me well enough by now to understand I don’t blow smoke by handing out gratuitous compliments. Great job.”

“As I have said in the past, your staff, PMs, and most importantly the hard and dedicated work of your field personnel have been, needless to say, most professional. As I walk through the community, every resident here really appreciated their professionalism, kindness, and the care they put into the quality of work they performed. After nearly 40 years in the construction industry myself, I was taught to put the same level of care and attention to detail, it is most apparent that you do as well. Much appreciated.”

“This commendation is for the crystal-clear communications employed by Eosso Brothers Paving as the company’s staff begins installation work next Monday. The notice placed on the windshield of our van today clearly stated when the project will begin and important notes that afforded me knowing what to expect. Eosso’s putting everything in writing suggests a laudable level of professionalism and sensitive awareness of residents’ concerns. My guess is the company will be as thorough on all phases of the job!”

“On behalf of myself and the Board of Trustees, we would like to thank you for a job well done! The belgium block curbing installation looks amazing and the new road in our very long entrance looks beautiful. Your crew was just great overall. They were pleasant to work with and very professional. Thank you again for a job well done and I look forward to working with you in the future on other projects.”

“We want to thank all the folks at Eosso who worked on the repaving project and contributed to such a great job. From a property manager’s standpoint, the fact that a project of this magnitude and complexity ran so smoothly and was completed in such a short amount of time truly confirms Eosso’s excellent reputation as being one of the very best of the best in the industry.”

Featured Projects

See why Eosso Brothers Paving is a leading pavement service provider in New Jersey, Eastern Pennsylvania, and Delaware.

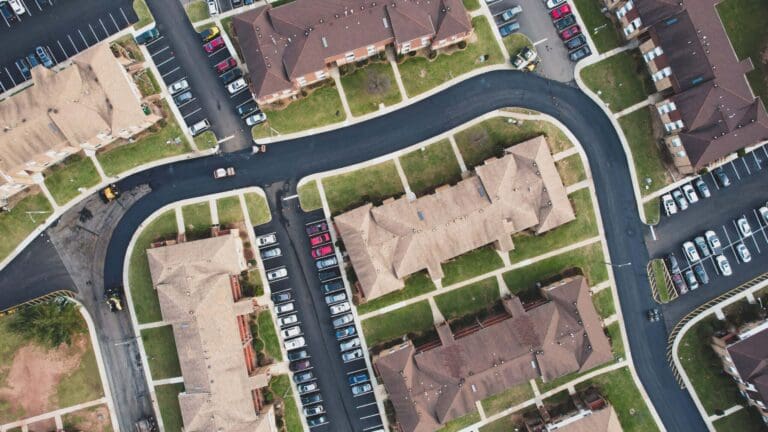

Case Study #1:

Edison, NJ Milling and Paving Project

Edison, NJ Milling and Paving Project

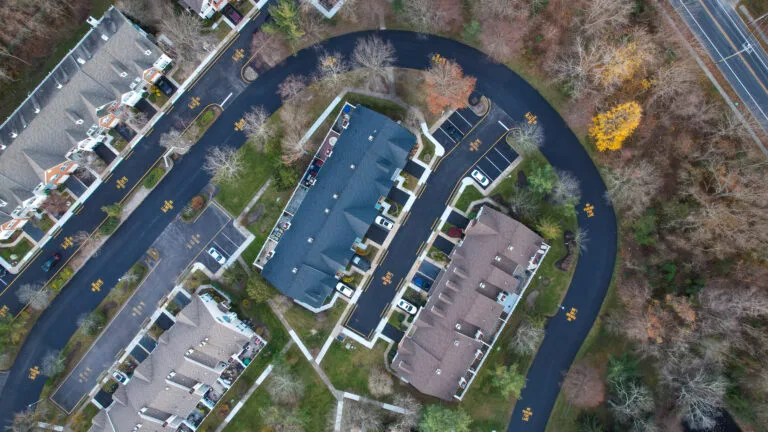

One of our last projects of 2021 was a milling & paving project in Edison, NJ. The asphalt parking lots and roadways were cracked and pavement failure was evident. Our team milled the top layer of asphalt, repaired the base layer, and installed a new top course. To maintain the curb appeal and extend the life of the pavement, we recommended a pavement maintenance plan to the community. By following the maintenance plan (including crack filling annually and sealcoating every 2-3 years), this community won’t have to worry about milling & paving again for a long time!

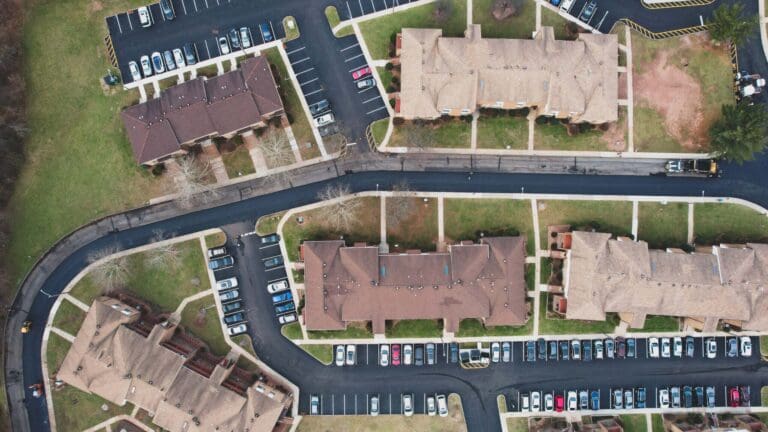

Case Study #2:

Toms River, NJ Paving Project

Toms River, NJ Paving Project

Our team has been working to improve the roadways in this Toms River, NJ community. They are on our pavement management plan- which allows them to budget a project to be completed every year, rather than paving the entire community all at once. This helps their budget AND keeps the residents a little less inconvenienced. The most recent section (and final section) of the community was the main road. Not only did we pave the roadway, but we also increased the parking spaces by working with the manager to redesign the parking layout and add additional parallel parking stalls on the roadway.

Get in Touch

Want to know more about our comprehensive services? Get in touch with a pavement specialist today.